Best

Damaged Goods Data

Products

Damaged Goods Data refers to information collected or recorded about products or goods that have been damaged during the manufacturing, transportation, storage, or handling processes. It includes details about the extent and nature of the damage, causes of damage, location of damage occurrence, and any associated costs or liabilities. Damaged Goods Data helps organizations assess the impact of product damage, identify areas for improvement, and make informed decisions to minimize losses and improve product quality. Read more

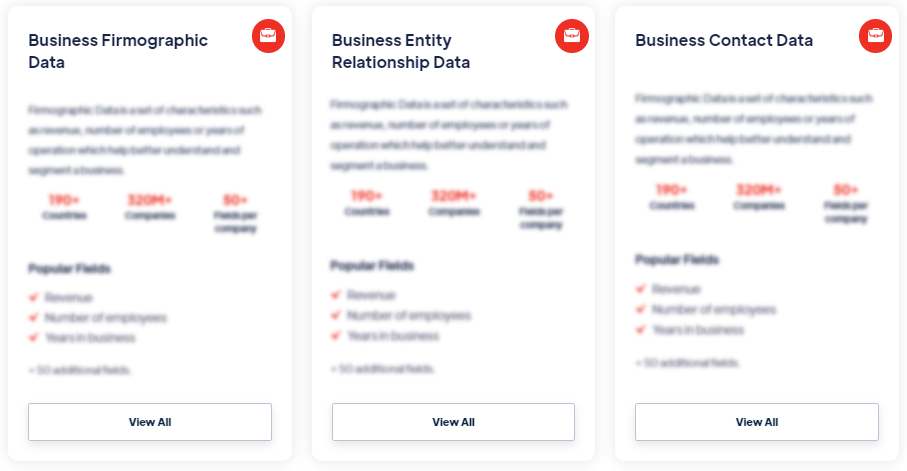

Our Data Integrations

Request Data Sample for

Damaged Goods Data

Browse the Data Marketplace

Frequently Asked Questions

1. What is Damaged Goods Data?

Damaged

Goods Data refers to information collected or recorded about

products or goods that have been damaged during the

manufacturing, transportation, storage, or handling processes.

It includes details about the extent and nature of the damage,

causes of damage, location of damage occurrence, and any

associated costs or liabilities. Damaged Goods Data helps

organizations assess the impact of product damage, identify

areas for improvement, and make informed decisions to minimize

losses and improve product quality.

2. What sources are commonly used to collect Damaged Goods

Data?

Damaged Goods Data can be collected from various sources within

an organization's supply chain and quality management

processes. Common sources include customer returns, warranty

claims, inspection reports, incident reports, quality control

records, and feedback from distributors, retailers, or

end-users. In addition, data may also be obtained from sensors,

monitoring systems, or automated detection mechanisms that

detect and record instances of product damage.

3. What are the key challenges in maintaining the quality and

accuracy of Damaged Goods Data?

Maintaining the quality and accuracy of Damaged Goods Data can

be challenging due to several factors. One challenge is ensuring

consistent and standardized data collection across different

sources and locations. This involves establishing clear

protocols, training personnel, and implementing standardized

reporting mechanisms. Another challenge is distinguishing

between pre-existing damage and damage incurred during the

handling or transportation processes. Proper documentation,

visual inspection, and traceability systems can help address

this challenge. Additionally, accurately quantifying the extent

of damage and its impact on the product's functionality or

value requires careful assessment and validation processes.

4. What privacy and compliance considerations should be taken

into account when handling Damaged Goods Data?

Handling Damaged Goods Data may involve sensitive information

related to product defects, customer complaints, or liability

claims. Organizations need to ensure compliance with data

protection and privacy regulations to safeguard

individuals' rights and confidential information. This

includes implementing appropriate data anonymization or

aggregation techniques to protect personal data, obtaining

necessary consents, and securely storing and transmitting the

data. Compliance with industry-specific regulations and

reporting requirements should also be considered when handling

Damaged Goods Data.

5. What technologies or tools are available for analyzing and

extracting insights from Damaged Goods Data?

Various technologies and tools can be used to analyze and

extract insights from Damaged Goods Data. Data analysis and

visualization software, such as Excel, Tableau, or Power BI, can

help in exploring patterns, trends, and correlations within the

data. Statistical analysis tools, like R or Python libraries

(e.g., pandas, numpy), can be employed for advanced analysis and

modeling. Additionally, machine learning algorithms can be used

to identify factors contributing to product damage and develop

predictive models for damage prevention.

6. What are the use cases for Damaged Goods Data?

Damaged Goods Data is valuable for organizations in several

ways. It helps identify recurring product defects or

vulnerabilities, enabling manufacturers to improve product

design, materials, or production processes. It also assists in

evaluating the effectiveness of packaging, transportation, or

storage practices and making necessary adjustments to reduce

product damage during logistics. Damaged Goods Data supports

warranty management by providing insights into common failure

points or issues that impact product performance. Additionally,

it aids in assessing the financial impact of product damage,

determining liability in cases of damage claims, and optimizing

risk mitigation strategies.

7. What other datasets are similar to Damaged Goods Data?

Datasets similar to Damaged Goods Data include quality control

data, product defect data, warranty claim data, customer

complaint data, and supply chain incident data. These datasets

focus on different aspects of product quality, performance, and

customer satisfaction. Analyzing and correlating these datasets

with Damaged Goods Data can provide a comprehensive

understanding of factors affecting product damage and quality

issues throughout the supply chain.