Best

Industrial Manufacturing Data

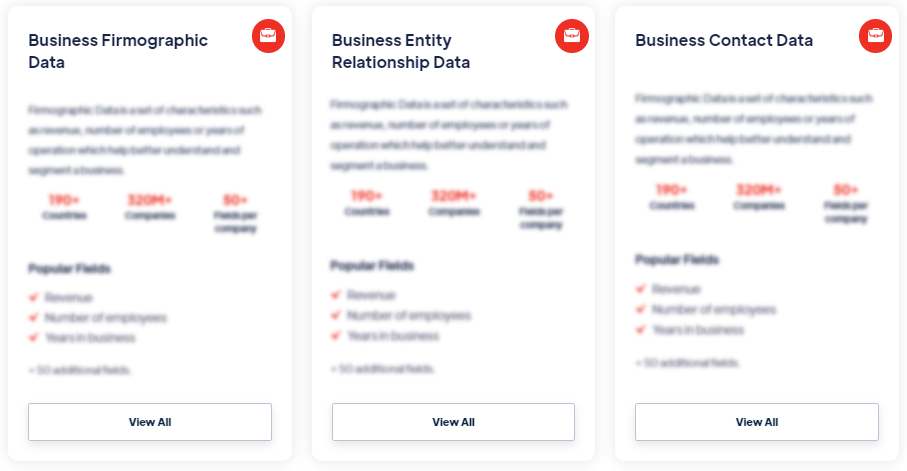

Products

Industrial manufacturing data refers to the data generated throughout the manufacturing process in industries such as automotive, electronics, pharmaceuticals, consumer goods, and more. It includes various types of data related to production, quality control, supply chain, inventory, maintenance, and other aspects of manufacturing operations. Read more

Our Data Integrations

Request Data Sample for

Industrial Manufacturing Data

Browse the Data Marketplace

Frequently Asked Questions

1. What is Industrial Manufacturing Data?

Industrial manufacturing data refers to the data generated

throughout the manufacturing process in industries such as

automotive, electronics, pharmaceuticals, consumer goods, and

more. It includes various types of data related to production,

quality control, supply chain, inventory, maintenance, and other

aspects of manufacturing operations.

2. What types of data are included in Industrial

Manufacturing Data?

Industrial manufacturing data includes production data (e.g.,

production volumes, cycle times), quality data (e.g., defect

rates, yield rates), inventory data (e.g., stock levels,

materials usage), maintenance data (e.g., equipment uptime,

downtime reasons), supply chain data (e.g., supplier

performance, lead times), and other relevant data points

specific to the manufacturing processes and operations.

3. How is Industrial Manufacturing Data collected?

Industrial manufacturing data is collected from various

sources, including sensors and monitoring systems deployed on

manufacturing equipment, production lines, and other relevant

areas. Data can be collected in real-time or periodically,

depending on the specific needs. Additionally, data can be

captured manually through operator inputs or collected

automatically through connected systems and machinery.

4. What is the importance of Industrial Manufacturing

Data?

Industrial manufacturing data plays a critical role in

optimizing production processes, ensuring product quality,

managing inventory levels, tracking equipment performance, and

making data-driven decisions. It enables manufacturers to

identify bottlenecks, improve efficiency, reduce waste, optimize

resource allocation, enhance product quality, and respond to

market demands effectively.

5. How is Industrial Manufacturing Data used?

Industrial manufacturing data is used for various purposes,

including process optimization, quality control, predictive

maintenance, supply chain management, demand forecasting, and

performance analysis. It serves as the foundation for

data-driven decision-making, continuous improvement initiatives,

and the implementation of advanced technologies such as

automation, machine learning, and artificial intelligence in the

manufacturing environment.

6. What are the challenges with Industrial Manufacturing

Data?

Challenges with industrial manufacturing data include data

integration and interoperability across different systems,

ensuring data accuracy and reliability, managing large volumes

of data generated by multiple sources, data security and privacy

concerns, and extracting meaningful insights from complex and

diverse datasets. Additionally, the adoption of standardized

data formats and protocols is crucial to enable seamless data

exchange and analysis.

7. What are the benefits of Industrial Manufacturing Data?

Industrial manufacturing data offers several benefits,

including improved operational efficiency, enhanced product

quality and reliability, reduced costs through optimized

resource utilization, better decision-making based on real-time

insights, increased agility to respond to market demands, and

the ability to drive innovation and continuous improvement in

manufacturing processes.