Best

Maintenance and Repair Data

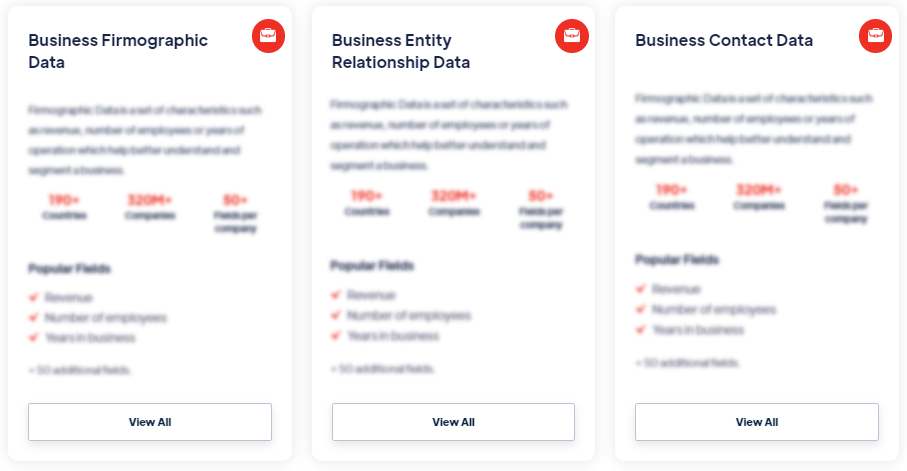

Products

Maintenance and Repair Data plays a crucial role in ensuring the optimal functioning and longevity of assets and equipment. It helps organizations track maintenance activities, identify potential issues, improve operational efficiency, minimize downtime, and reduce repair costs. Read more

Our Data Integrations

Request Data Sample for

Maintenance and Repair Data

Browse the Data Marketplace

Frequently Asked Questions

1. Why is Maintenance and Repair Data important?

Maintenance and Repair Data plays a crucial role in ensuring

the optimal functioning and longevity of assets and equipment.

It helps organizations track maintenance activities, identify

potential issues, improve operational efficiency, minimize

downtime, and reduce repair costs.

2. How is Maintenance and Repair Data collected?

Maintenance and Repair Data can be collected through various

sources such as work order systems, asset management software,

equipment sensors, maintenance logs, technician reports, and

historical maintenance records.

3. How is Maintenance and Repair Data managed and stored?

Maintenance and Repair Data is typically managed and stored in

dedicated maintenance management systems or enterprise asset

management systems. These systems provide functionalities to

record, organize, and track maintenance activities and related

information.

4. How is Maintenance and Repair Data used?

Maintenance and Repair Data is used to schedule preventive

maintenance tasks, plan and execute repairs, track equipment

performance, analyze maintenance trends, optimize maintenance

schedules, and make informed decisions regarding asset

maintenance and replacement.

5. What are the benefits of analyzing Maintenance and Repair

Data?

Analyzing Maintenance and Repair Data can help organizations

identify patterns or trends in equipment failures, optimize

maintenance schedules, improve asset reliability, reduce repair

costs, and enhance overall operational efficiency.

6. What are the challenges in managing Maintenance and Repair

Data?

Challenges in managing Maintenance and Repair Data include

ensuring data accuracy and completeness, integrating data from

various sources, tracking and documenting maintenance activities

in real-time, and aligning maintenance practices with business

objectives.

7. What are the best practices for utilizing Maintenance and

Repair Data?

Best practices include implementing a centralized maintenance

management system, capturing detailed maintenance records,

conducting regular data quality checks, leveraging predictive

maintenance techniques, fostering a culture of proactive

maintenance, and using data analytics to drive insights and

continuous improvement.

â€