Best

Maintenance Schedule Data

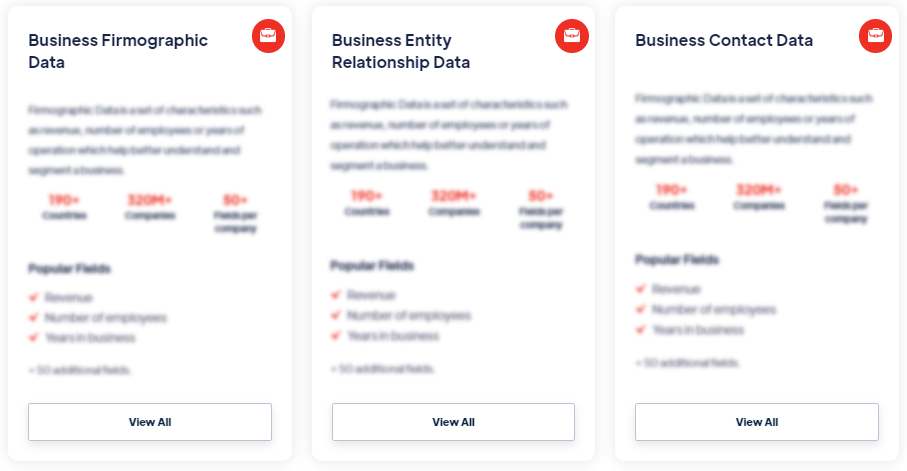

Products

Maintenance Schedule Data is important because it helps organizations proactively plan and execute maintenance activities, ensuring the optimal performance and reliability of assets. It enables timely maintenance interventions, reduces unplanned downtime, and extends the lifespan of equipment. Read more

Our Data Integrations

Request Data Sample for

Maintenance Schedule Data

Browse the Data Marketplace

Frequently Asked Questions

1. Why is Maintenance Schedule Data important?

Maintenance Schedule Data is important because it helps

organizations proactively plan and execute maintenance

activities, ensuring the optimal performance and reliability of

assets. It enables timely maintenance interventions, reduces

unplanned downtime, and extends the lifespan of equipment.

2. How is Maintenance Schedule Data created?

Maintenance Schedule Data is typically created based on factors

such as manufacturer recommendations, equipment specifications,

regulatory requirements, historical maintenance data, and

industry best practices. It involves considering factors like

asset criticality, usage patterns, maintenance costs, and safety

requirements.

3. How is Maintenance Schedule Data managed and stored?

Maintenance Schedule Data is often managed and stored in

computerized maintenance management systems (CMMS) or enterprise

asset management systems (EAM). These systems provide a

centralized repository for scheduling, tracking, and managing

maintenance activities.

4. How is Maintenance Schedule Data used?

Maintenance Schedule Data is used to create maintenance plans,

assign tasks to maintenance teams, schedule resources and

equipment, track compliance with maintenance schedules, and

ensure timely execution of maintenance activities. It helps

organizations stay organized, proactive, and efficient in their

maintenance operations.

5. What are the benefits of using Maintenance Schedule

Data?

Using Maintenance Schedule Data offers several benefits,

including improved asset reliability, reduced downtime,

optimized resource allocation, better coordination among

maintenance teams, enhanced safety, and cost savings through

preventive maintenance and efficient scheduling.

6. What are the challenges in managing Maintenance Schedule

Data?

Challenges in managing Maintenance Schedule Data include

aligning maintenance schedules with production or operational

schedules, accommodating unforeseen changes or disruptions,

ensuring data accuracy and consistency, and effectively

communicating maintenance schedules to relevant stakeholders.

7. What are the best practices for utilizing Maintenance

Schedule Data?

Best practices for utilizing Maintenance Schedule Data include

regularly reviewing and updating maintenance schedules,

leveraging historical data and performance trends for

optimization, integrating with other operational systems for

seamless coordination, empowering maintenance teams with mobile

access to schedules and updates, and fostering a culture of

proactive maintenance and continuous improvement.

â€