Best

Manufacturing Company Data

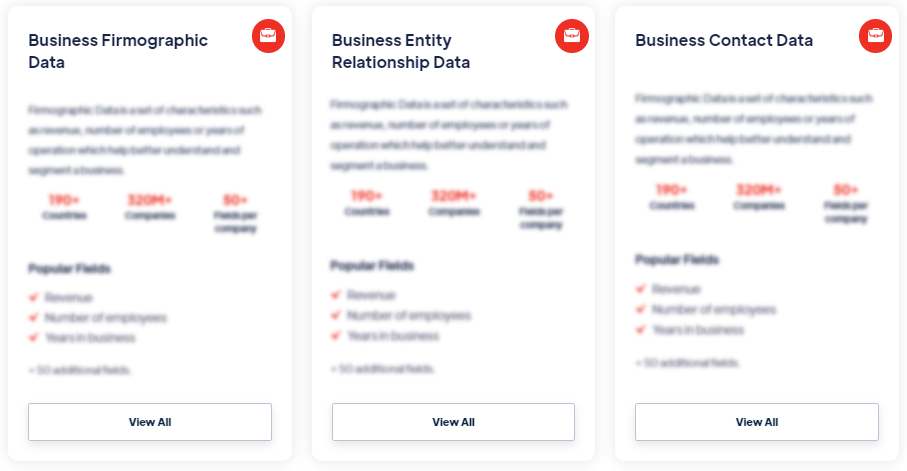

Products

Manufacturing Company Data is important for various reasons. It provides insights into the performance, operations, and financial health of manufacturing companies. It helps stakeholders, investors, researchers, and policymakers make informed decisions related to investments, market analysis, competitive intelligence, and economic planning. It also aids in understanding industry trends, supply chain dynamics, and the overall health of the manufacturing sector. Read more

Our Data Integrations

Request Data Sample for

Manufacturing Company Data

Browse the Data Marketplace

Frequently Asked Questions

1. Why is Manufacturing Company Data important?

Manufacturing Company Data is important for various reasons. It

provides insights into the performance, operations, and

financial health of manufacturing companies. It helps

stakeholders, investors, researchers, and policymakers make

informed decisions related to investments, market analysis,

competitive intelligence, and economic planning. It also aids in

understanding industry trends, supply chain dynamics, and the

overall health of the manufacturing sector.

2. How is Manufacturing Company Data collected?

Manufacturing Company Data is collected from various sources,

including company filings, financial reports, industry

databases, market research reports, government records, and

publicly available information. Data collection methods may

involve manual data entry, web scraping, data aggregators,

surveys, and partnerships with data providers. In some cases,

companies may voluntarily share their data for research or

benchmarking purposes.

3. How is Manufacturing Company Data managed and stored?

Manufacturing Company Data is typically managed and stored in

databases, data warehouses, or cloud-based platforms. Robust

data management practices ensure the accuracy, integrity, and

security of the data. Companies may have internal systems to

organize and manage their own data, while external data

providers or research organizations may maintain centralized

databases for broader access and analysis.

4. How is Manufacturing Company Data used?

Manufacturing Company Data is used for a range of purposes. It

helps investors assess the financial performance and growth

potential of manufacturing companies, guiding investment

decisions. Market researchers analyze this data to understand

market trends, consumer behavior, and competitive landscapes.

Policymakers and economic analysts use it to evaluate the health

of the manufacturing sector and make strategic decisions.

Manufacturers themselves utilize the data for benchmarking,

market analysis, and improving operational efficiency.

5. What are the challenges in managing Manufacturing Company

Data?

Managing Manufacturing Company Data comes with challenges. One

challenge is ensuring data accuracy and reliability, as

companies may have different reporting standards or data quality

issues. Data privacy and compliance with regulations, such as

GDPR, can also be a challenge when handling sensitive company

information. Additionally, the rapidly changing nature of the

manufacturing industry requires keeping the data up to date and

relevant.

6. What are the best practices for utilizing Manufacturing

Company Data?

Best practices for utilizing Manufacturing Company Data include

validating data from multiple sources to ensure accuracy and

reliability. Employing data quality control measures, such as

data cleaning and normalization, helps maintain data integrity.

It is important to respect data privacy and comply with legal

and ethical guidelines when using company-specific data.

Collaborating with industry experts, utilizing advanced

analytics techniques, and staying updated with industry trends

can enhance the value derived from Manufacturing Company Data.

7. What are the future trends in Manufacturing Company Data

analysis?

In the future, Manufacturing Company Data analysis is expected

to leverage advanced analytics techniques such as predictive

modeling, machine learning, and artificial intelligence to gain

deeper insights. Real-time monitoring and analysis of

manufacturing data through the Industrial Internet of Things

(IIoT) are likely to play a significant role. Integration of

data from various sources, such as supply chain data, customer

feedback, and production metrics, will enable a holistic

understanding of manufacturing operations and facilitate

data-driven decision-making.

â€