Best

Oil Refinery Data

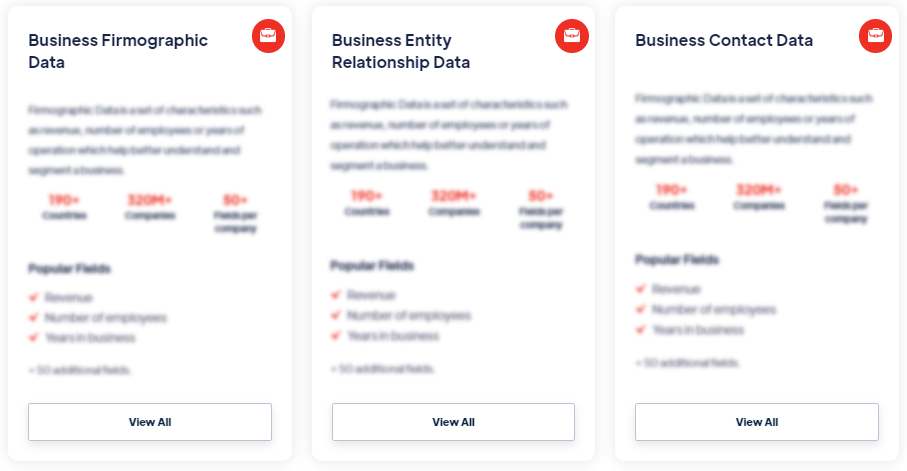

Products

Oil refinery data refers to information and statistics that provide insights into the refining processes and operations involved in converting crude oil into refined petroleum products. It includes data on refinery capacities, production volumes of various products (such as gasoline, diesel, jet fuel, and petrochemicals), feedstock types, refining technologies, energy consumption, emissions, and other performance indicators. Read more

Our Data Integrations

Request Data Sample for

Oil Refinery Data

Browse the Data Marketplace

Frequently Asked Questions

1. What is Oil Refinery Data?

Oil refinery

data refers to information and statistics that provide insights

into the refining processes and operations involved in

converting crude oil into refined petroleum products. It

includes data on refinery capacities, production volumes of

various products (such as gasoline, diesel, jet fuel, and

petrochemicals), feedstock types, refining technologies, energy

consumption, emissions, and other performance indicators.

2. How is Oil Refinery Data collected?

Oil

refinery data is collected from a variety of sources, including

refinery operators, industry associations, government agencies,

and energy research organizations. Data collection methods

include surveys, operational reports, emissions monitoring,

energy audits, and other measurement techniques. Collaboration

and data-sharing agreements between stakeholders contribute to

comprehensive and accurate oil refinery data collection.

3. What does Oil Refinery Data represent?

Oil refinery data represents the operational and performance

aspects of refineries, providing insights into their capacity,

efficiency, output, and environmental impact. It helps

stakeholders understand the production capabilities of

refineries, the composition of refined products, the quality of

feedstocks used, energy consumption patterns, emissions levels,

and overall refinery performance.

4. How is Oil Refinery Data used?

Oil

refinery data is used by a wide range of stakeholders, including

oil companies, energy analysts, government agencies,

researchers, and policymakers. It helps stakeholders analyze the

refining sector's capacity to meet demand for various

petroleum products, assess refining economics and profitability,

monitor energy efficiency and emissions, and inform policy

decisions related to refinery expansions, environmental

regulations, and energy transitions.

5. What are the benefits of Oil Refinery Data?

Oil refinery data provides valuable insights into the refining

industry, enabling stakeholders to monitor production trends,

identify market opportunities, optimize refining operations, and

evaluate environmental performance. It helps refine planning and

investment decisions, assess refining capacities, optimize

feedstock selection, improve energy efficiency, reduce

emissions, and support sustainable development in the refining

sector.

6. What are the challenges with Oil Refinery Data?

Oil refinery data faces challenges such as data accuracy and

consistency, limited transparency in some regions, and

variations in reporting practices. Refineries may have different

data collection and reporting systems, making it challenging to

compare and analyze data across facilities. Additionally, data

on energy consumption and emissions can be complex to measure

and report accurately, and ensuring data privacy and security is

crucial in handling sensitive refinery data.

7. How is Oil Refinery Data managed and shared?

Oil refinery data is managed by various entities, including

refinery operators, industry associations, and government

agencies. Data management involves collecting, validating,

storing, and analyzing refinery data. Sharing and dissemination

of data occur through industry reports, publications, databases,

and online platforms. Collaboration and data-sharing initiatives

foster transparency, facilitate benchmarking, and enable

stakeholders to access and utilize oil refinery data

effectively.